How Long Do DTF Transfers Last? A Complete Guide for Businesses

You have undoubtedly heard of DTF (Direct-to-Film) transfers if you work in the printing industry or are wanting to order custom clothing. They are a well-liked option for vivid, high-quality prints on a variety of textiles. However, a frequently asked topic is: How long do DTF transfers last?

This post will explain how long DTF prints survive, what factors influence it, and how to extend its lifespan. By the end, you'll see why DTF is a fantastic option for your company's requirements.

DTF Transfers: What Are They?

Using heat and sticky powder, a design is printed onto a specific film and then transferred onto fabric in DTF printing. DTF enables intricate, full-color graphics without the need for numerous layers or screens, in contrast to conventional techniques like screen printing or vinyl.

What Is the Duration of DTF Transfers?

Depending on a number of variables, DTF transfers may continue for two to five years or longer. Some prints retain their colour after more than fifty washings if they are properly cared for. What affects their durability is as follows:

1. Material Quality

Film & Ink: Premium DTF films and inks don't fade or fracture.

Adhesive Powder: A powerful adhesive guarantees that the print will remain attached to the fabric.

Fabric Type: Blends, cotton, and polyester are the best for retaining DTF prints.

2. Cleaning and Maintenance

The machine Wash Cold: The adhesive may become weakened by hot water.

Turn Inside Out: Makes clothing less abrasive.

Mild Detergent: The print may be harmed by harsh chemicals.

Steer clear of fabric softeners and bleaches since they gradually degrade the glue.

3. The Drying Process

Air Dry: Dryers' heat might lead to cracking. Set the dryer on low heat if you're using one.

4. The Process of Printing and Curing

A proper heat press guarantees that the transfer is completely bonded to the fabric.

Curing Time: Prints that are not fully cured may peel more quickly.

DTF vs. Alternative Printing Techniques

1. Durability DTF Transfers: With the right maintenance, last two to five years or more.

Screen printing is the most resilient, lasting five to ten years or more.

Vinyl: Depending on use and washing, it usually lasts one to three years.

Sublimation: Only works on polyester textiles, but it can last for more than five years.

2. Vibrancy of Colour

Excellent DTF transfers with vibrant, full-color prints.

Screen printing is good, but it lacks photo-realistic details and gradients.

Vinyl: Best for solid designs; limited colour selection.

Excellent sublimation with vivid, long-lasting colours (but only on polyester).

3. Compatibility of Fabrics

Cotton, polyester, mixes, and even some non-fabrics can be transferred with DTF.

Cotton works best for screen printing, whereas synthetic blends work less well.

Vinyl: It can seem stiff, but it works on most materials.

Only polyester or things coated in polyester can be sublimated.

4. Level of Detail

DTF Transfers: Exceptionally detailed, ideal for small lettering and intricate graphics.

Screen printing: has trouble with fine gradients and medium detail.

Vinyl: Low detail, ideal for basic logos and forms.

High detail and excellent for photo-quality prints, sublimation is only available on polyester.

What Should You Pick?

The most durable option for long-lasting bulk orders (such as uniforms) is screen printing.

Sublimation (if using polyester) for all-over designs or stretchable textiles.

Vinyl is more affordable for short-run, low-volume custom prints, but it is less robust.

DTF is the greatest all-around option for softness, detail, and versatility; it works well for high-quality patterns, diverse materials, and small batches.

We offer premium prints for businesses if you require DTF transfers of the highest calibre that strike a mix between affordability, colour, and durability. Request a quote right now!

How Can DTF Transfers Be Extended?

To extend the life of your DTF prints, heed these tips:

Fabrics should be pre-washed to get rid of chemicals that could hinder adherence.

To guarantee uniform pressure and temperature, use a heat press rather than an iron.

Properly store transfers by keeping them out of direct sunlight and in a cool, dry location.

Observe the washing instructions; mild detergents and gentle cycles are helpful.

Why Should Your Company Use DTF?

Cost-effective: ideal for modest orders; no screens are required.

Versatile: It can be used on blends, cotton, polyester, and even some non-fabrics.

High Detail: Ideal for lifelike prints and complex logos.

Soft Feel: DTF prints don't create stiffness like vinyl does.

This post will explain how long DTF prints survive, what factors influence it, and how to extend its lifespan. By the end, you'll see why DTF is a fantastic option for your company's requirements.

DTF Transfers: What Are They?

Using heat and sticky powder, a design is printed onto a specific film and then transferred onto fabric in DTF printing. DTF enables intricate, full-color graphics without the need for numerous layers or screens, in contrast to conventional techniques like screen printing or vinyl.

What Is the Duration of DTF Transfers?

Depending on a number of variables, DTF transfers may continue for two to five years or longer. Some prints retain their colour after more than fifty washings if they are properly cared for. What affects their durability is as follows:

1. Material Quality

Film & Ink: Premium DTF films and inks don't fade or fracture.

Adhesive Powder: A powerful adhesive guarantees that the print will remain attached to the fabric.

Fabric Type: Blends, cotton, and polyester are the best for retaining DTF prints.

2. Cleaning and Maintenance

The machine Wash Cold: The adhesive may become weakened by hot water.

Turn Inside Out: Makes clothing less abrasive.

Mild Detergent: The print may be harmed by harsh chemicals.

Steer clear of fabric softeners and bleaches since they gradually degrade the glue.

3. The Drying Process

Air Dry: Dryers' heat might lead to cracking. Set the dryer on low heat if you're using one.

4. The Process of Printing and Curing

A proper heat press guarantees that the transfer is completely bonded to the fabric.

Curing Time: Prints that are not fully cured may peel more quickly.

DTF vs. Alternative Printing Techniques

1. Durability DTF Transfers: With the right maintenance, last two to five years or more.

Screen printing is the most resilient, lasting five to ten years or more.

Vinyl: Depending on use and washing, it usually lasts one to three years.

Sublimation: Only works on polyester textiles, but it can last for more than five years.

2. Vibrancy of Colour

Excellent DTF transfers with vibrant, full-color prints.

Screen printing is good, but it lacks photo-realistic details and gradients.

Vinyl: Best for solid designs; limited colour selection.

Excellent sublimation with vivid, long-lasting colours (but only on polyester).

3. Compatibility of Fabrics

Cotton, polyester, mixes, and even some non-fabrics can be transferred with DTF.

Cotton works best for screen printing, whereas synthetic blends work less well.

Vinyl: It can seem stiff, but it works on most materials.

Only polyester or things coated in polyester can be sublimated.

4. Level of Detail

DTF Transfers: Exceptionally detailed, ideal for small lettering and intricate graphics.

Screen printing: has trouble with fine gradients and medium detail.

Vinyl: Low detail, ideal for basic logos and forms.

High detail and excellent for photo-quality prints, sublimation is only available on polyester.

What Should You Pick?

The most durable option for long-lasting bulk orders (such as uniforms) is screen printing.

Sublimation (if using polyester) for all-over designs or stretchable textiles.

Vinyl is more affordable for short-run, low-volume custom prints, but it is less robust.

DTF is the greatest all-around option for softness, detail, and versatility; it works well for high-quality patterns, diverse materials, and small batches.

We offer premium prints for businesses if you require DTF transfers of the highest calibre that strike a mix between affordability, colour, and durability. Request a quote right now!

How Can DTF Transfers Be Extended?

To extend the life of your DTF prints, heed these tips:

Fabrics should be pre-washed to get rid of chemicals that could hinder adherence.

To guarantee uniform pressure and temperature, use a heat press rather than an iron.

Properly store transfers by keeping them out of direct sunlight and in a cool, dry location.

Observe the washing instructions; mild detergents and gentle cycles are helpful.

Why Should Your Company Use DTF?

Cost-effective: ideal for modest orders; no screens are required.

Versatile: It can be used on blends, cotton, polyester, and even some non-fabrics.

High Detail: Ideal for lifelike prints and complex logos.

Soft Feel: DTF prints don't create stiffness like vinyl does.

RECENT POSTS

Application

-

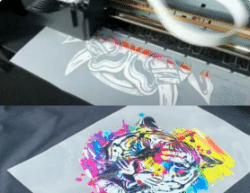

DTF Printer Effect ShowDirect to film printer(DTF printers) are T-shirt transfer printers,Hstar DTF printer offer a transfer solution especially for dark color fabric,which is a creative application process.

DTF Printer Effect ShowDirect to film printer(DTF printers) are T-shirt transfer printers,Hstar DTF printer offer a transfer solution especially for dark color fabric,which is a creative application process. -

Hstar printer in Turkey ExhibitionIn September, our company participated in the Turkish advertising exhibition. At the exhibition, many people are interested in our machine.

Hstar printer in Turkey ExhibitionIn September, our company participated in the Turkish advertising exhibition. At the exhibition, many people are interested in our machine.

More Application