What Are the Advantages of DTF Printers?

Most likely, if you work in the clothing decorating industry, you are aware of Direct-to-Film (DTF) printing. Because it is more cost-effective, versatile, and of higher quality than more conventional printing methods like screen printing, DTG (Direct-to-Garment), or heat transfer vinyl, this novel approach is becoming more and more well-liked.

The main benefits of DTF printers and the reasons they might be the ideal investment for your company will be discussed in this article.1. Suitable for Nearly Any Fabric

In contrast to DTG printing, which is most effective on cotton, DTF transfers adhere to a variety of textiles, such as:

Blends of cotton and polyester (such as 50/50 cotton and polyester)

Denim Leather, Nylon (properly pretreated)

Because of this, DTF is perfect for hats, purses, sportswear, and personalized clothing.

2. More vivid, brighter colours (including white ink)

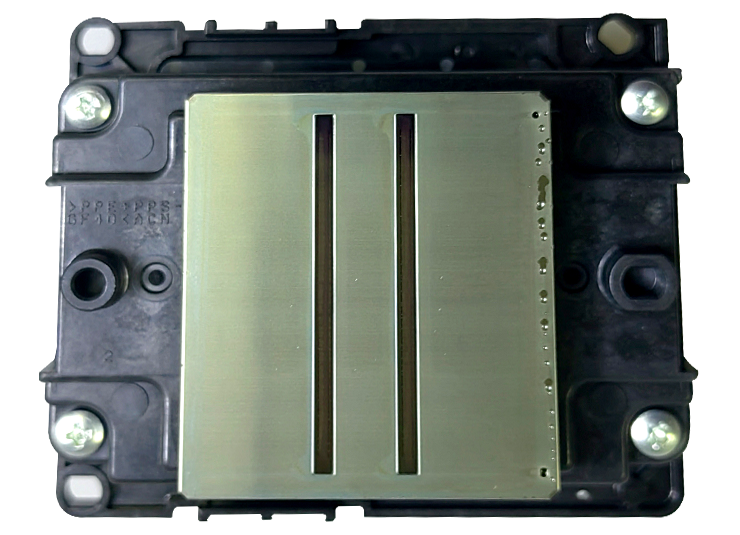

White ink underbase is used by DTF printers to produce vivid prints on coloured and dark textiles. DTF produces opaque, high-contrast graphics with exceptional colour saturation, in contrast to DTG, which may appear faded on black garments.

3. Fabric Pretreatment Is Not Necessary

Clothing must be pre-treated before printing using DTG, which adds expenses and additional steps. This is removed by DTF; simply print on the film, dust with adhesive powder, and press. This minimizes material waste and saves time.

4. Sturdy, Long-Lasting Prints

Because the ink adheres firmly to the fabric fibres, DTF transfers are incredibly resilient.

Strong adherence is guaranteed by the sticky powder.

Prints don't peel or crack after several washings.

Because of this, DTF is ideal for long-lasting workwear, sportswear, and daily clothing.

5. Excellent for Both Big and Small Orders 3. Fabric Pretreatment Is Not Necessary

Clothing must be pre-treated before printing using DTG, which adds expenses and additional steps. This is removed by DTF; simply print on the film, dust with adhesive powder, and press. This minimizes material waste and saves time.

4. Sturdy, Long-Lasting Prints

Because the ink adheres firmly to the fabric fibres, DTF transfers are incredibly resilient.

Strong adherence is guaranteed by the sticky powder.

Prints don't peel or crack after several washings.

Because of this, DTF is ideal for long-lasting workwear, sportswear, and daily clothing.

There are no setup costs (unlike screen printing, which needs screens for every colour).

Print one shirt or a thousand with the same level of efficiency—there is no minimum order quantity.

quicker turnaround because there is no need to clean platens or switch screens between tasks.

6. Economical for Companies

Despite the seemingly expensive initial cost, a DTF printer ultimately saves money because:

less expensive per unit than screen printing or DTG for modest quantities.

Reduced ink waste because print heads don't need to be flushed as frequently.

No costly screens or preparation chemicals.

7. Detailed and intricate designs

Photorealistic graphics, gradients, and tiny details can all be printed on DTF without sacrificing quality. DTF enables full-color patterns without the requirement for cutting, in contrast to heat transfer vinyl (HTV), which necessitates weeding.

8. Simple to Print in-house or outsource

You can get custom DTF transfers from suppliers if you're not ready to purchase a DTF printer. As your business expands, you can bring production in-house to have complete control over turnaround times and quality.

9. More environmentally friendly than some substitutes

less water waste than printing on a screen.

No PVC, in contrast to certain vinyl transfers.

Because misprints can frequently be fixed before pressing, there is less fabric waste.

10. Increasing Demand in the Market

Because of its brilliant prints, durability, and soft feel, DTF is becoming more and more popular among companies and consumers. You can keep ahead of the competition and draw in more business by using DTF early.

In summary, is it worthwhile to get a DTF printer?

DTF is one of the greatest options available today if you're looking for a flexible, excellent, and affordable printing process. Regardless of the size of your company, DTF can help you increase customer satisfaction, lower expenses, and provide a wider range of products.Are you prepared to begin? Look through our selection of the greatest DTF printers and materials for your company!

RECENT POSTS

Application

-

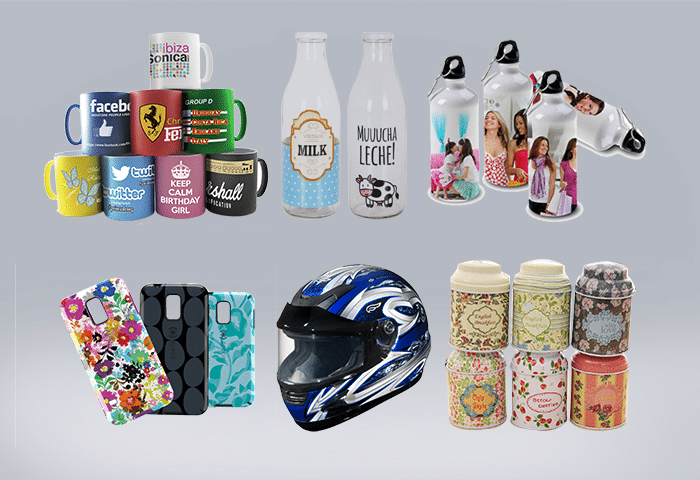

Application scenarios of UV DTF printersUV DTF printer is our NEW machine, which is loved by many consumers.crystal stickers are widely used.

Application scenarios of UV DTF printersUV DTF printer is our NEW machine, which is loved by many consumers.crystal stickers are widely used.

Crystal stickers can also be used as decorations to make your gift more beautiful and special. -

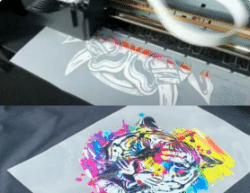

DTF Printer Effect ShowDirect to film printer(DTF printers) are T-shirt transfer printers,Hstar DTF printer offer a transfer solution especially for dark color fabric,which is a creative application process.

DTF Printer Effect ShowDirect to film printer(DTF printers) are T-shirt transfer printers,Hstar DTF printer offer a transfer solution especially for dark color fabric,which is a creative application process.

More Application