Can 3D Printers Print Metal?

Manufacturing has been transformed by 3D printing, which enables companies to produce intricate parts efficiently and affordably. One frequently asked topic, nevertheless, is whether metal can be printed using 3D printers.

In this manual, we will discuss:

The operation of metal 3D printing

Various 3D printing technologies for metal

Typical metals for 3D printing

Uses for 3D printing metal

Benefits and drawbacks of conventional manufacturing

By the end, you'll be able to determine if it makes sense for your business to invest in metal 3D printing.

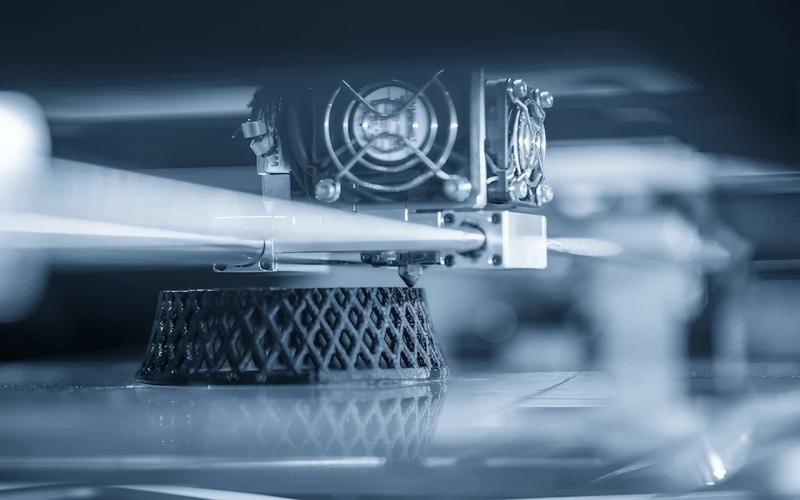

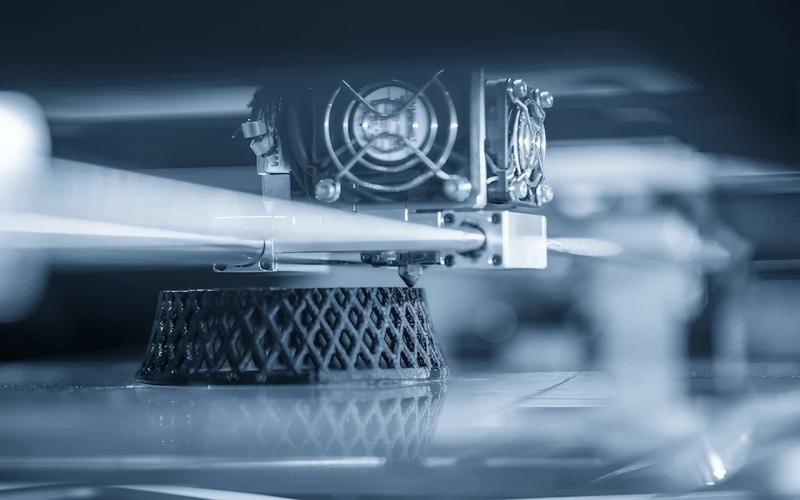

What Is the Process of 3D Printing Metal?

Metal 3D printing employs sophisticated techniques to fuse metal wires or powders into solid structures, in contrast to plastic 3D printing, which melts filament layer by layer. The most widely used methods consist of:

1. Selective Laser Melting (SLM) and Direct Metal Laser Sintering (DMLS)

Layer by layer, tiny metal powder is melted and fused by a powerful laser.

Perfect for intricate, high-strength components (medical implants, aerospace).

Materials: Cobalt chrome, titanium, aluminium, and stainless steel.

2. Jetting of the Binder

Metal powder particles are held together by a liquid binding agent.

The metal is subsequently fused by heating (sintered) the printed component.

a little weaker than DMLS/SLM, but faster and less expensive.

Materials: copper, tool steel, and stainless steel.

3. Modelling of Metal Fused Deposition (FDM)

It employs metal-filled filament and is comparable to FDM for plastic.

Solid metal is left behind when the plastic binder is burned off the printed portion using heat.

cheaper for prototyping but less accurate than DMLS.

Materials: copper, bronze, and stainless steel.

4. Electron Beam Melting (EBM) Melts

metal powder using an electron beam rather than a laser.

Perfect for titanium and superalloys, it operates in a vacuum chamber.

prevalent in the medical and aerospace sectors.

Typical Applications: medical instruments and auto parts

Titanium's main characteristics are its strength and light weight.

Typical applications include medical implants and aerospace components.

Aluminium

Important characteristics are low weight and high heat conductivity.

Typical Applications: Drone parts and auto parts

Important Properties of Cobalt Chrome: Biocompatible and resistant to heat

Typical Applications: dental implants and turbine blades

Key characteristics of nickel alloys include tolerance to high temperatures.

Typical Applications: Oil and gas equipment, jet engine parts

Important characteristics of copper Outstanding electrical conductivity

Common Applications: Heat exchangers and electronics

Applications for 3D Printing Metal

Industries are changing as a result of metal 3D printing since it allows:

1. Defence & Aerospace

lightweight, powerful parts for rockets and jets.

Turbine blades have intricate cooling channels.

2. Health and Dental

custom implants (spinal devices, hip joints).

intricately designed surgical instruments.

3. Automobile

lightweight automotive components to improve fuel economy.

performance parts that have been customised (exhausts, brake systems).

4. Manufacturing in Industry

robust moulds and tools.

On-demand spare parts minimise downtime.

5. Energy & Electronics

conductors and heat sinks.

specialised cooling solutions for electronics with high performance.

Benefits and Drawbacks of 3D Printing Metal

✔ Complex geometries: Traditional machining cannot achieve these.

Because only the necessary metal powder is used, there is less material waste.

✔ Quick prototyping: quicker than CNC cutting.

✔ Customisation: Designs are easily changed.

The drawbacks High cost: Materials and machinery are costly. Post-processing is necessary; frequently, machining and polishing are needed. Restricted size: Large components can require assembly.

✖ Better for small batches; slower for large output.

Is 3D Printing Metal the Correct Option for Your Company?

If you require: Custom, high-performance metal items, metal 3D printing is perfect.

Robust yet lightweight components. Quick prototyping without costly equipment.

However, conventional techniques (such as CNC machining) might still be superior if you require low-cost, high-volume production.

Concluding remarks

Metal can be printed using 3D printers, but only if the proper technology is used. Businesses can produce robust, accurate metal parts for industrial, automotive, medical, and aerospace applications using techniques like DMLS, binder jetting, and EBM.

Metal 3D printing is a game-changer for many industries because it provides unparalleled design freedom, decreased waste, and speedier prototyping, despite its higher initial cost.

In this manual, we will discuss:

The operation of metal 3D printing

Various 3D printing technologies for metal

Typical metals for 3D printing

Uses for 3D printing metal

Benefits and drawbacks of conventional manufacturing

By the end, you'll be able to determine if it makes sense for your business to invest in metal 3D printing.

What Is the Process of 3D Printing Metal?

Metal 3D printing employs sophisticated techniques to fuse metal wires or powders into solid structures, in contrast to plastic 3D printing, which melts filament layer by layer. The most widely used methods consist of:

1. Selective Laser Melting (SLM) and Direct Metal Laser Sintering (DMLS)

Layer by layer, tiny metal powder is melted and fused by a powerful laser.

Perfect for intricate, high-strength components (medical implants, aerospace).

Materials: Cobalt chrome, titanium, aluminium, and stainless steel.

2. Jetting of the Binder

Metal powder particles are held together by a liquid binding agent.

The metal is subsequently fused by heating (sintered) the printed component.

a little weaker than DMLS/SLM, but faster and less expensive.

Materials: copper, tool steel, and stainless steel.

3. Modelling of Metal Fused Deposition (FDM)

It employs metal-filled filament and is comparable to FDM for plastic.

Solid metal is left behind when the plastic binder is burned off the printed portion using heat.

cheaper for prototyping but less accurate than DMLS.

Materials: copper, bronze, and stainless steel.

4. Electron Beam Melting (EBM) Melts

metal powder using an electron beam rather than a laser.

Perfect for titanium and superalloys, it operates in a vacuum chamber.

prevalent in the medical and aerospace sectors.

What Metals Can Be 3D Printed?

Key characteristics of stainless steel include its strength and resistance to corrosion.Typical Applications: medical instruments and auto parts

Titanium's main characteristics are its strength and light weight.

Typical applications include medical implants and aerospace components.

Aluminium

Important characteristics are low weight and high heat conductivity.

Typical Applications: Drone parts and auto parts

Important Properties of Cobalt Chrome: Biocompatible and resistant to heat

Typical Applications: dental implants and turbine blades

Key characteristics of nickel alloys include tolerance to high temperatures.

Typical Applications: Oil and gas equipment, jet engine parts

Important characteristics of copper Outstanding electrical conductivity

Common Applications: Heat exchangers and electronics

Applications for 3D Printing Metal

Industries are changing as a result of metal 3D printing since it allows:

1. Defence & Aerospace

lightweight, powerful parts for rockets and jets.

Turbine blades have intricate cooling channels.

2. Health and Dental

custom implants (spinal devices, hip joints).

intricately designed surgical instruments.

3. Automobile

lightweight automotive components to improve fuel economy.

performance parts that have been customised (exhausts, brake systems).

4. Manufacturing in Industry

robust moulds and tools.

On-demand spare parts minimise downtime.

5. Energy & Electronics

conductors and heat sinks.

specialised cooling solutions for electronics with high performance.

Benefits and Drawbacks of 3D Printing Metal

✔ Complex geometries: Traditional machining cannot achieve these.

Because only the necessary metal powder is used, there is less material waste.

✔ Quick prototyping: quicker than CNC cutting.

✔ Customisation: Designs are easily changed.

The drawbacks High cost: Materials and machinery are costly. Post-processing is necessary; frequently, machining and polishing are needed. Restricted size: Large components can require assembly.

✖ Better for small batches; slower for large output.

Is 3D Printing Metal the Correct Option for Your Company?

If you require: Custom, high-performance metal items, metal 3D printing is perfect.

Robust yet lightweight components. Quick prototyping without costly equipment.

However, conventional techniques (such as CNC machining) might still be superior if you require low-cost, high-volume production.

Concluding remarks

Metal can be printed using 3D printers, but only if the proper technology is used. Businesses can produce robust, accurate metal parts for industrial, automotive, medical, and aerospace applications using techniques like DMLS, binder jetting, and EBM.

Metal 3D printing is a game-changer for many industries because it provides unparalleled design freedom, decreased waste, and speedier prototyping, despite its higher initial cost.

RECENT POSTS

Application

-

UV DTF Printer Client FeedbackA customer from Austria placed an order for our UV DTF printer after many inspections. This is their feedback after using it.

UV DTF Printer Client FeedbackA customer from Austria placed an order for our UV DTF printer after many inspections. This is their feedback after using it. -

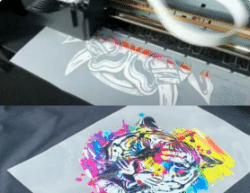

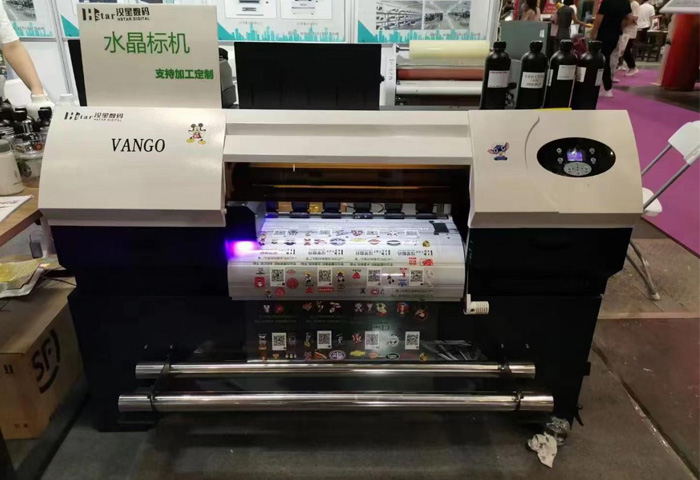

Vango DTF printerOur DTF printer adopts an all-in-one printing design, which is more space-saving and easier to operate.This is our printing show.

Vango DTF printerOur DTF printer adopts an all-in-one printing design, which is more space-saving and easier to operate.This is our printing show.

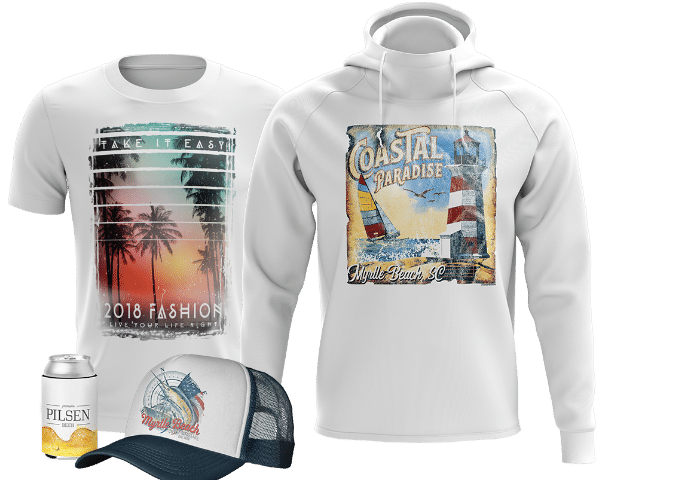

Wide applications,design for textile printing,Suitable for all kinds of fabrics, T-shirts,leather, bags and shoes etc.

More Application