Is DTF Printer Better Than Sublimation Printer?

DTF (Direct-to-Film) printing and sublimation printing are two common choices when deciding on a printing technique for your company. Although each has special benefits, which is most suitable for your requirements? To assist you with making a decision, we will compare DTF and sublimation printers in this post.

How Does DTF Printing Work?

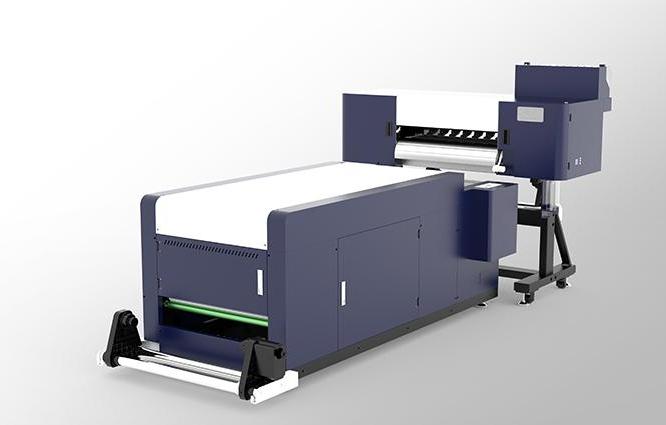

DTF printing entails printing a design onto a unique film, which is subsequently heated to transfer it onto fabric. The procedure consists of:

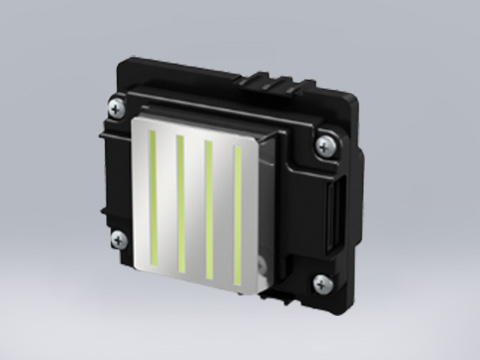

Printing: DTF inks are used to print the design onto PET film.

Applying Powder: The wet ink is covered with a dusting of hot-melted sticky powder.

Curing: The powder is melted and bonded to the ink by heating the film.

Transferring: A heat press is used to transfer the design onto the fabric.

Benefits of Printing DTF

Works with blends, cotton, polyester, and even dark textiles.

Unlike sublimation, pre-treated fabrics are not required.

High resilience to washing and durability

Brilliant hues with excellent opacity

No colour restrictions (light and white can be printed on dark textiles)

Sublimation printing: What is it?

Heat is used in sublimation printing to transfer dye onto materials coated with polyester or polymers. The procedure entails:

Printing: Special inks are used to print a design onto sublimation paper.

Heat Pressing: High temperatures are used to press the paper onto the cloth, converting the ink into a gas that adheres to the fabric.

Benefits of Printing using Sublimation

Ideal for products made entirely of polyester or covered with polyester

Permanent, smooth prints that are resistant to peeling and cracking

Vibrant colours with a lot of detail

No hand feel or texture because the print blends into the fabric.

Key Distinctions Between Sublimation and DTF

1. Compatibility of fabrics

DTF can be used on nearly any type of fabric, including mixes, cotton, polyester, and light and dark materials.

Only polyester and polyester-coated materials can be sublimated.

2. Colour Restrictions

On dark textiles, DTF may print light and white colours.

White cannot be printed by sublimation; only light-colored polyester can be used.

3. Sturdiness and Feel

Although it feels a little thicker, DTF is incredibly resilient.

With no additional texture, sublimation feels like a natural part of the fabric.

4. Production Cost & Speed

For small batches and multi-color patterns, DTF is quicker.

For large quantities of polyester, sublimation is an economical option.

What Should You Pick?

Select DTF Printing If Necessary:

✔ Printing on mixed materials, cotton, or dark textiles

✏ Light-colored or white patterns on dark clothing

✔ An adaptable solution for many kinds of fabric

Select sublimation printing if you require:

✔ Superior prints on polyester (such as for phone cases, mugs, and sportswear)

✔ A smooth, texture-free finish

✔ Large quantities of polyester-based goods

In conclusion

Sublimation and DTF printers each have advantages. While sublimation works best on polyester with incredibly smooth prints, DTF is more adaptable and may be used on a variety of materials, including dark ones. Your decision is based on your company's requirements, such as if you specialize in polyester items or need fabric flexibility.

DTF is a better option if you require a printer that can handle many types of fabric. Sublimation is still a popular choice for companies who specialize in polyester.

How Does DTF Printing Work?

DTF printing entails printing a design onto a unique film, which is subsequently heated to transfer it onto fabric. The procedure consists of:

Printing: DTF inks are used to print the design onto PET film.

Applying Powder: The wet ink is covered with a dusting of hot-melted sticky powder.

Curing: The powder is melted and bonded to the ink by heating the film.

Transferring: A heat press is used to transfer the design onto the fabric.

Benefits of Printing DTF

Works with blends, cotton, polyester, and even dark textiles.

Unlike sublimation, pre-treated fabrics are not required.

High resilience to washing and durability

Brilliant hues with excellent opacity

No colour restrictions (light and white can be printed on dark textiles)

Sublimation printing: What is it?

Heat is used in sublimation printing to transfer dye onto materials coated with polyester or polymers. The procedure entails:

Printing: Special inks are used to print a design onto sublimation paper.

Heat Pressing: High temperatures are used to press the paper onto the cloth, converting the ink into a gas that adheres to the fabric.

Benefits of Printing using Sublimation

Ideal for products made entirely of polyester or covered with polyester

Permanent, smooth prints that are resistant to peeling and cracking

Vibrant colours with a lot of detail

No hand feel or texture because the print blends into the fabric.

Key Distinctions Between Sublimation and DTF

1. Compatibility of fabrics

DTF can be used on nearly any type of fabric, including mixes, cotton, polyester, and light and dark materials.

Only polyester and polyester-coated materials can be sublimated.

2. Colour Restrictions

On dark textiles, DTF may print light and white colours.

White cannot be printed by sublimation; only light-colored polyester can be used.

3. Sturdiness and Feel

Although it feels a little thicker, DTF is incredibly resilient.

With no additional texture, sublimation feels like a natural part of the fabric.

4. Production Cost & Speed

For small batches and multi-color patterns, DTF is quicker.

For large quantities of polyester, sublimation is an economical option.

What Should You Pick?

Select DTF Printing If Necessary:

✔ Printing on mixed materials, cotton, or dark textiles

✏ Light-colored or white patterns on dark clothing

✔ An adaptable solution for many kinds of fabric

Select sublimation printing if you require:

✔ Superior prints on polyester (such as for phone cases, mugs, and sportswear)

✔ A smooth, texture-free finish

✔ Large quantities of polyester-based goods

In conclusion

Sublimation and DTF printers each have advantages. While sublimation works best on polyester with incredibly smooth prints, DTF is more adaptable and may be used on a variety of materials, including dark ones. Your decision is based on your company's requirements, such as if you specialize in polyester items or need fabric flexibility.

DTF is a better option if you require a printer that can handle many types of fabric. Sublimation is still a popular choice for companies who specialize in polyester.

RECENT POSTS

Application

-

Hstar printer in Turkey ExhibitionIn September, our company participated in the Turkish advertising exhibition. At the exhibition, many people are interested in our machine.

Hstar printer in Turkey ExhibitionIn September, our company participated in the Turkish advertising exhibition. At the exhibition, many people are interested in our machine. -

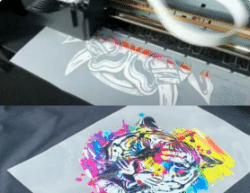

DTF Printer Effect ShowDirect to film printer(DTF printers) are T-shirt transfer printers,Hstar DTF printer offer a transfer solution especially for dark color fabric,which is a creative application process.

DTF Printer Effect ShowDirect to film printer(DTF printers) are T-shirt transfer printers,Hstar DTF printer offer a transfer solution especially for dark color fabric,which is a creative application process.

More Application